Motorola APX 8000 Manual: A Comprehensive Guide

This guide provides detailed instructions for the Motorola APX 8000 radio, covering setup, programming, advanced features, and maintenance. Recent developments include increased software accessibility, potentially available at no cost via Motorola’s official channels.

Accessing the Customer Programming Software (CPS) often involves checking the Motorola forum for a “Sticky” post with download links, or exploring authorized dealers like Kenwood. The APX NEXT XN, Motorola’s latest firefighter radio, meets stringent industry standards.

The Motorola APX 8000 is a sophisticated, mission-critical portable radio designed for professional users demanding reliable communication in challenging environments. It represents a significant advancement in public safety radio technology, offering a robust feature set and interoperability across various communication systems. This radio is particularly popular among first responders, including firefighters and law enforcement personnel, due to its durability and advanced capabilities.

Understanding the APX 8000 requires acknowledging Motorola Solutions’ evolving approach to software accessibility. Historically, obtaining the Customer Programming Software (CPS) necessary for radio configuration was a complex process. However, recent trends suggest a shift towards greater openness, with potential access to the APX CPS now available at no cost through platforms like myview.motorolasolutions.com, although user experiences vary.

Furthermore, the introduction of the APX NEXT XN, Motorola’s newest radio specifically tailored for firefighters, highlights the company’s commitment to meeting the stringent demands of the fire industry. This manual will guide you through the intricacies of the APX 8000, ensuring you can effectively utilize its features and maintain optimal performance. It’s important to note that accessing software resources often involves consulting the Motorola forum for updated information and links.

Understanding the APX 8000’s Key Features

The APX 8000 boasts a comprehensive suite of features designed for critical communication. These include advanced audio processing for clarity in noisy environments, integrated GPS for location tracking, and robust encryption capabilities to ensure secure transmissions. Its interoperability allows seamless communication across different radio systems, a vital asset for multi-agency operations.

A crucial function is the Recal/Recon mode, used for identifying and potentially tracking radios within a system. When activated on a suspect radio, it typically displays an orange color, signaling its status. Understanding color codes and system access is paramount for effective radio operation and network management.

Programming the APX 8000 requires the Customer Programming Software (CPS), access to which has been a point of discussion. While historically challenging to obtain, recent reports suggest potential no-cost access through Motorola’s official channels, though experiences vary. Alternatively, the Motorola forum’s “Sticky” post often provides valuable download links, and authorized dealers, like Kenwood, may offer the software for purchase. Proper software is essential to unlock the full potential of the APX 8000’s features.

Getting Started with Your APX 8000

Initial setup involves powering on the radio and familiarizing yourself with the user interface. Successful operation relies on understanding basic transmission and reception procedures, alongside proper programming via CPS software.

Initial Setup and Powering On

Before first use, ensure the APX 8000 is equipped with a fully charged battery. Insert the battery securely into the radio’s battery compartment, verifying proper alignment. To power on the unit, locate the power/volume knob – typically situated on the top or side of the radio – and rotate it clockwise past the ‘off’ position. The display screen will illuminate, initiating the startup sequence.

During startup, the radio performs a self-test, checking internal components and software integrity. Allow this process to complete uninterrupted. Upon successful completion, the radio will display the currently selected channel or system. If the display shows an error message, consult the troubleshooting section of this manual or contact Motorola support.

Initial configuration may require selecting a language and setting the date and time. These settings can usually be accessed through the radio’s menu system, navigated using the directional pad and enter/exit buttons. Familiarize yourself with these controls to efficiently customize your radio’s settings. Proper initial setup ensures optimal performance and usability from the outset.

Navigating the User Interface

The APX 8000’s user interface centers around a high-resolution color display and a multi-functional control knob, complemented by dedicated buttons for essential functions. The control knob allows for menu navigation, volume adjustment, and channel selection. Pressing the knob typically acts as an ‘enter’ or ‘select’ function, confirming your choices.

Menu access is usually achieved by pressing a dedicated ‘Menu’ button. Within the menu, use the directional pad (up, down, left, right) to scroll through options; Submenus are indicated by arrows or highlighted text. To exit a menu or submenu, press the ‘Exit’ or ‘Back’ button.

Key functions like transmitting and receiving are initiated via the push-to-talk (PTT) button and the radio’s speaker, respectively. The display provides real-time information, including channel number, signal strength, and system status. Familiarizing yourself with the icon-based system and menu structure is crucial for efficient operation. Experiment with the controls to gain proficiency.

Basic Operation: Transmitting and Receiving

To transmit using the APX 8000, firmly press and hold the Push-To-Talk (PTT) button. Ensure you’ve selected the correct channel or talkgroup before transmitting. Speak clearly into the microphone, maintaining a consistent distance for optimal audio quality. Releasing the PTT button immediately ends transmission.

Receiving signals is automatic when a transmission is occurring on the selected channel. Audio will be audible through the radio’s speaker or a connected earpiece. The display will indicate the receiving signal strength and potentially identify the transmitting party, depending on system configuration.

Monitoring channels can be done by simply turning the channel selector knob. The radio will scan for activity on the selected channel. Understanding color codes and system access is vital for proper communication; Always adhere to established communication protocols and procedures. Practice these basic operations to become comfortable with the radio’s functionality.

Programming the APX 8000

Programming the APX 8000 requires Motorola’s CPS (Customer Programming Software). Accessing this software often involves the Motorola forum or authorized dealers, like Kenwood, for availability.

Accessing CPS (Customer Programming Software)

Obtaining the Customer Programming Software (CPS) for the Motorola APX 8000 can present some challenges, but several avenues exist for users to acquire the necessary tools for radio configuration. Historically, Motorola’s approach to CPS distribution was more restrictive, often requiring authorized dealers or service centers to provide access. However, recent indications suggest a shift towards greater openness, with reports of the software becoming available at no cost through Motorola’s official website, specifically myview.motorolasolutions.com.

Despite these reports, user experiences vary, and some individuals have encountered access restrictions on the website. Therefore, a reliable and consistently recommended method for obtaining the CPS is to consult the Motorola forum. Within the forum, a “Sticky” post typically contains direct download links or detailed instructions on how to acquire the software. This forum-based resource is frequently updated and maintained by knowledgeable community members.

Alternatively, exploring third-party dealers, such as Kenwood, may yield positive results. Many dealers are permitted to sell the CPS online, providing a convenient option for users who prefer a direct purchase. It’s important to verify the software’s compatibility and authenticity when sourcing it from third-party vendors. Remember to always exercise caution and download software from trusted sources to avoid potential security risks.

Downloading Motorola Software – Official Sources

Locating official Motorola software downloads for the APX 8000 requires navigating Motorola Solutions’ online resources. While a direct, easily accessible download portal isn’t always apparent, myview.motorolasolutions.com has been cited as a potential source for obtaining the CPS (Customer Programming Software) at no cost. However, user reports indicate inconsistent access, with some encountering restrictions and messages indicating unavailability.

Therefore, verifying access through this channel is crucial before relying on it. Motorola’s official support website remains a primary resource for software updates, firmware upgrades, and documentation. Users may need to create an account and register their APX 8000 radio to unlock access to specific downloads. Navigating the support site can be complex, requiring precise model number and software version information.

Furthermore, Motorola frequently updates its software distribution methods. Checking the official Motorola Solutions website for announcements regarding software availability is recommended. Always prioritize downloading software directly from Motorola to ensure authenticity, security, and compatibility with your APX 8000 radio. Be wary of unofficial sources, as they may contain malware or incompatible software versions.

Using the Motorola Forum for Software Access

The Motorola forum consistently emerges as a key resource for APX 8000 users seeking access to the Customer Programming Software (CPS). Numerous posts and discussions highlight a “Sticky” thread containing crucial download links and instructions. This “Sticky” is regularly updated by forum moderators and experienced users, providing a centralized location for software acquisition.

However, access to the software through the forum often requires registration and adherence to community guidelines. Users should carefully read the instructions within the “Sticky” thread, as they may involve specific download procedures or account requirements. The forum also serves as a valuable platform for troubleshooting software installation issues and seeking assistance from fellow APX 8000 owners.

It’s important to note that links within the forum may become outdated or broken over time. Regularly checking the “Sticky” thread for the latest information is essential. Furthermore, users should exercise caution when downloading files from any online source, including forums, and verify their integrity before installation. The Motorola forum remains a vital community-driven resource for APX 8000 software access and support.

Third-Party Dealers and Software Availability (Kenwood Example)

While Motorola increasingly focuses on direct software access, authorized third-party dealers remain a viable option for obtaining the APX 8000’s Customer Programming Software (CPS). These dealers, like Kenwood, often have established procedures for selling the software to qualified customers, typically radio technicians or public safety organizations.

The availability and pricing of the CPS through third-party dealers can vary significantly. It’s advisable to contact multiple dealers to compare options and ensure compatibility with your specific APX 8000 model and firmware version. Dealers may require proof of affiliation with a public safety agency or a valid technician certification before processing a software purchase.

Purchasing through a dealer often includes technical support and assistance with software installation and configuration, which can be beneficial for users unfamiliar with the CPS. However, this convenience typically comes at a higher cost compared to accessing the software directly through Motorola’s channels. Exploring both direct and dealer options allows users to choose the most suitable method based on their needs and budget.

Advanced Features and Functionality

The APX 8000 offers Recal/Recon mode for identifying radios on a system, and the newer APX NEXT XN is designed for firefighters. Troubleshooting and understanding color codes are crucial for optimal system access.

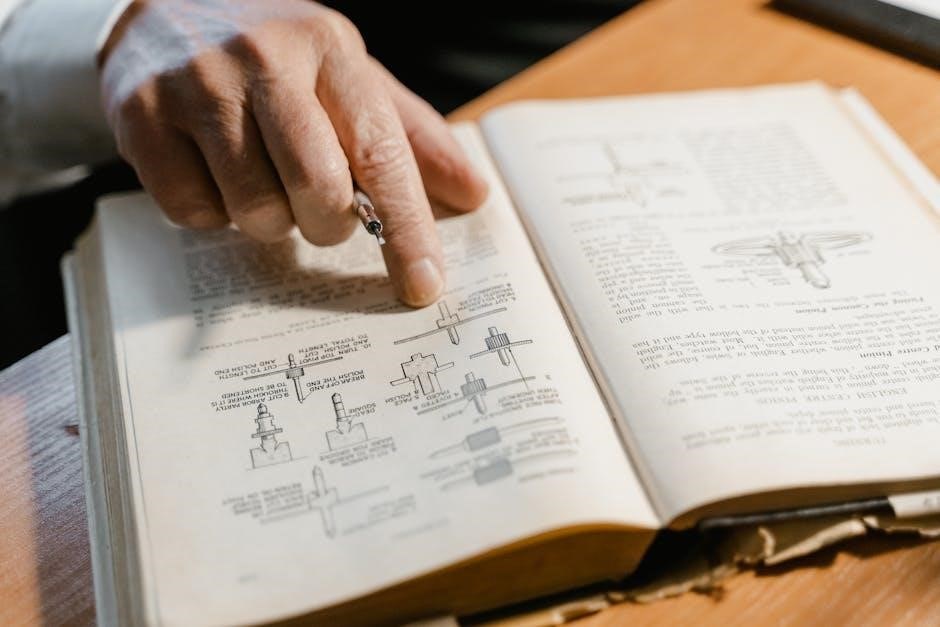

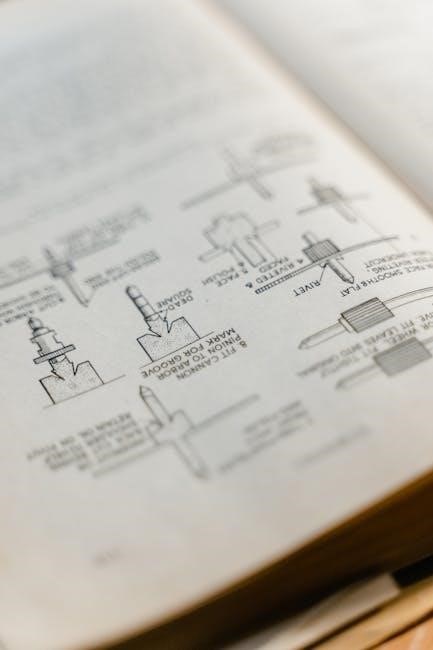

Recal/Recon Mode: Understanding and Usage

Recal/Recon mode on the Motorola APX 8000 is a powerful diagnostic tool used to identify and re-synchronize radios within a trunked radio system. When initiated, a radio enters a specific state, visually indicated by its display turning orange. This signifies that the radio is actively broadcasting its presence and attempting to re-establish communication with the system.

The primary purpose of Recal/Recon is to ensure that the radio’s information – such as its serial number and assigned talkgroups – is correctly registered within the system’s database. This is particularly useful when adding new radios to a system, or when a radio has experienced communication issues. It’s also employed when troubleshooting potential alignment problems.

To initiate Recal/Recon, specific programming within the CPS (Customer Programming Software) is required. The process involves placing the radio into a designated mode, often triggered by a specific key combination or menu selection. It’s important to note that multiple radios may need to be placed into Recal/Recon simultaneously for effective synchronization. Users should consult the official Motorola documentation or a qualified radio technician for detailed instructions and safety precautions before attempting this procedure.

Successfully entering Recal/Recon mode, as evidenced by the orange display, confirms the radio is broadcasting its identification. This allows the system to update its records and ensure seamless communication.

APX NEXT XN: Newest Firefighter Radio

The APX NEXT XN represents Motorola Solutions’ latest advancement in firefighter radio technology, building upon the foundation of the APX 8000 series. Designed specifically to meet the rigorous demands of the fire service, the XN incorporates enhanced features and adheres to the most stringent industry standards for reliability and performance in critical environments.

Key improvements in the APX NEXT XN include enhanced audio clarity, improved interoperability with other communication systems, and increased durability to withstand harsh conditions encountered during firefighting operations. It boasts advanced noise cancellation and signal processing capabilities, ensuring clear communication even in loud and chaotic scenes.

This new radio prioritizes firefighter safety by providing a dependable communication lifeline. Motorola Solutions emphasizes that the XN is engineered for seamless integration into existing radio infrastructure, minimizing disruption during upgrades. While the APX 8000 remains a robust and capable radio, the NEXT XN offers a significant leap forward in technology and functionality.

Information regarding programming and operation of the APX NEXT XN will be detailed in its dedicated manual, though many core principles remain consistent with the APX 8000 series.

Troubleshooting Common Issues

Common issues with the Motorola APX 8000 often relate to programming errors, battery performance, or radio recognition within a system; If experiencing transmission or reception problems, verify correct channel selection and system access – ensuring proper color code configuration is crucial. Recal/Recon mode can sometimes resolve issues with radio authentication, though proper procedure is essential.

Battery life concerns frequently stem from improper charging habits or aging batteries. Utilize Motorola-approved chargers and avoid prolonged storage with a fully discharged battery. If the radio fails to power on, check the battery connection and consider testing with a known-good battery.

Software glitches can occasionally occur; ensuring you have the latest CPS version and a valid license is vital. The Motorola forum is a valuable resource for troubleshooting software-related problems, with users often sharing solutions and workarounds. Remember to consult official documentation before attempting advanced troubleshooting steps.

For persistent issues, contacting a qualified Motorola service technician is recommended to diagnose and repair hardware failures or complex software conflicts.

Understanding Color Codes and System Access

Color codes, within the Motorola APX 8000 system, act as a digital “key,” enabling selective access to specific talkgroups. They prevent unwanted users from hearing sensitive communications, enhancing privacy and operational efficiency. Proper configuration of color codes in your radio’s programming is essential for successful system access.

System access relies on a combination of correct frequencies, color codes, and potentially, site IDs. Incorrect settings will result in the radio being unable to connect to the desired talkgroup or even the entire system. Recal/Recon mode can sometimes be necessary when a radio is moved to a new system or experiences authentication issues.

The APX 8000 supports various system types, including conventional, trunked, and multi-site systems. Each system type may have unique access requirements. Consult your system administrator for accurate color code and system ID information. Incorrect programming can lead to communication failures and potential safety hazards.

Understanding these parameters is crucial for effective radio operation and ensuring seamless communication within your organization’s network.

Maintenance and Safety

Regular maintenance, including proper battery management and careful cleaning, extends the APX 8000’s lifespan. Adherence to fire industry standards ensures safe and reliable operation in critical situations.

Prioritize compliance for optimal performance.

Battery Management and Charging

Optimal battery performance is crucial for the reliability of your Motorola APX 8000 radio. Lithium-ion batteries, commonly used in the APX 8000, require specific care to maximize their lifespan and prevent potential hazards. Always use Motorola-approved chargers designed specifically for the APX 8000 battery. Using incompatible chargers can damage the battery and potentially create a safety risk.

Avoid completely discharging the battery before recharging. Frequent deep discharges can significantly reduce the battery’s overall capacity. Instead, consider implementing a charging schedule that keeps the battery topped up. Store spare batteries in a cool, dry place, away from direct sunlight and extreme temperatures; Temperature extremes can negatively impact battery performance and longevity.

When charging, monitor the battery’s status and disconnect the charger once the battery is fully charged. Overcharging can also contribute to battery degradation. Inspect the battery regularly for any signs of damage, such as swelling, leakage, or corrosion. If damage is detected, discontinue use immediately and replace the battery with a genuine Motorola replacement. Proper battery handling ensures both the safety of the user and the continued reliable operation of the APX 8000 radio.

Cleaning and Care of Your APX 8000

Maintaining the physical integrity of your Motorola APX 8000 radio is essential for its long-term performance and reliability. Regular cleaning prevents the buildup of dirt, dust, and debris that can interfere with button operation and potentially damage internal components. Use a soft, damp cloth to wipe down the exterior of the radio. Avoid using harsh chemicals, solvents, or abrasive cleaners, as these can damage the finish and potentially compromise the radio’s seals.

Pay particular attention to cleaning the speaker grill and microphone port, ensuring they are free from obstructions. For stubborn dirt or grime, lightly dampen the cloth with a mild soap solution, then wipe the surface clean and dry thoroughly. Inspect the antenna connector for corrosion or damage, and clean it gently if necessary. Ensure the radio is powered off before cleaning.

When storing the APX 8000, keep it in a clean, dry environment, protected from extreme temperatures and direct sunlight. Avoid dropping or subjecting the radio to physical shock, as this can cause internal damage. Regularly inspect the radio for any signs of wear and tear, and address any issues promptly to prevent further damage. Proper care will extend the life of your APX 8000 and ensure its continued reliable operation.

Compliance with Fire Industry Standards

The Motorola APX 8000 is engineered to meet rigorous standards crucial for firefighter safety and effective communication during emergency situations. Specifically, the newer APX NEXT XN model is designed to surpass the most demanding requirements within the fire industry. These standards encompass durability, reliability, and performance under extreme conditions, including heat, water exposure, and physical impact.

Compliance involves adherence to specifications related to audio clarity, ensuring clear voice transmission in noisy environments, and interoperability with other communication systems used by fire departments and emergency responders. The radio undergoes extensive testing to verify its ability to withstand harsh conditions and maintain functionality when it matters most. Meeting these standards is not merely a technical achievement but a commitment to the safety of firefighters.

Motorola Solutions actively participates in the development and refinement of these industry benchmarks, ensuring their products remain at the forefront of safety technology. Users should consult relevant documentation and certifications to confirm the specific standards met by their APX 8000 model. Proper operation and maintenance, as outlined in this manual, are also vital for maintaining compliance and ensuring optimal performance in critical situations.