Overview of the Juki DDL-8700 Instruction Manual

The Juki DDL-8700 manual is a comprehensive guide for operating and maintaining the sewing machine, covering installation, operation, and maintenance procedures. It includes safety precautions, technical specifications, and troubleshooting tips to ensure optimal performance and longevity of the machine.

1.1. Purpose and Scope of the Manual

The Juki DDL-8700 instruction manual is designed to provide users with clear guidance on operating, maintaining, and troubleshooting the sewing machine. Its scope includes essential information for safe usage, installation, and optimal performance, ensuring users can utilize the machine effectively for industrial sewing applications. The manual covers key aspects such as technical specifications, safety precautions, and maintenance routines to enhance productivity and machine longevity.

1.2. Target Audience

The Juki DDL-8700 manual is intended for professional sewists, industrial workers, and technicians involved in heavy-duty sewing tasks. It caters to users requiring precise control over stitching, fabric handling, and machine maintenance. The guide is also useful for new operators needing to understand setup procedures and experienced technicians performing advanced troubleshooting and repairs, ensuring efficient and safe operation of the machine.

1.3. Manual Structure and Navigation

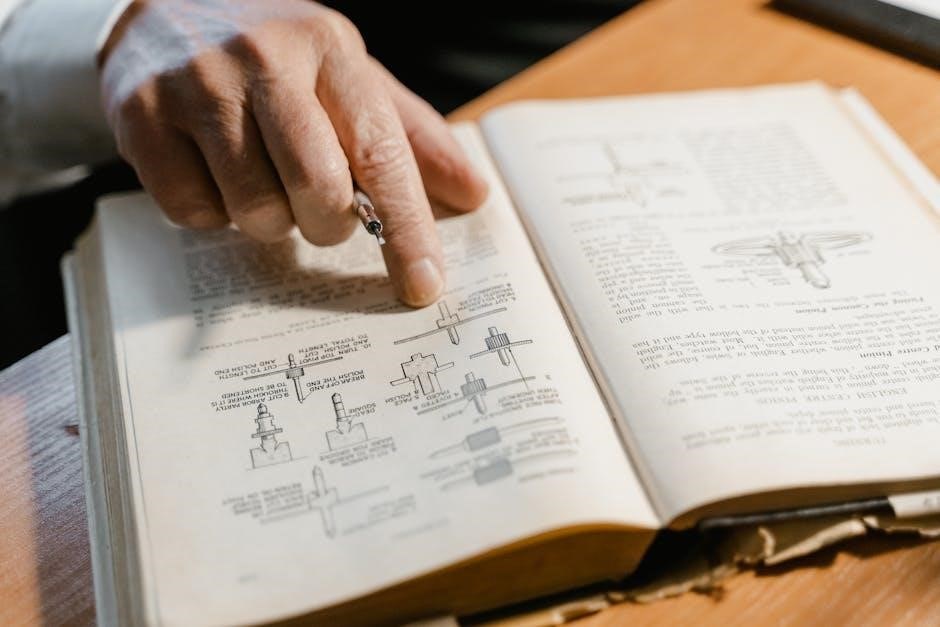

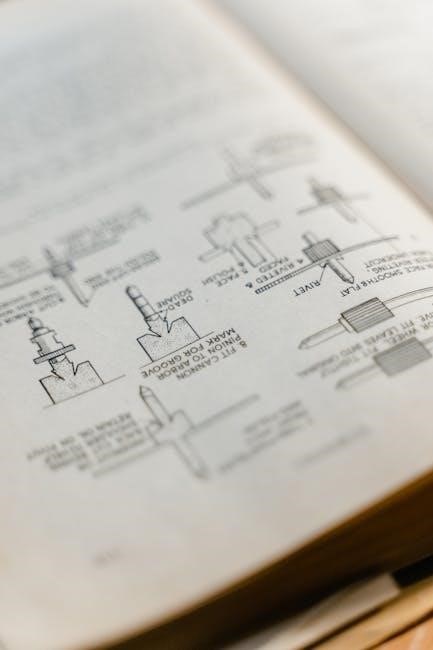

The Juki DDL-8700 manual is organized into clear sections, including setup, operation, and maintenance, with detailed diagrams and step-by-step instructions. It features a table of contents and indexed pages for easy navigation, ensuring users can quickly locate specific information. The manual also includes highlighted safety guidelines and technical specifications, making it user-friendly for both novices and experienced operators to efficiently utilize the machine.

Key Features of the Juki DDL-8700 Sewing Machine

The Juki DDL-8700 offers high-speed stitching, versatile stitch types, and a durable industrial-grade construction, ensuring reliability and precision for heavy-duty sewing applications.

2.1. High-Speed Performance

The Juki DDL-8700 delivers exceptional sewing speed, making it ideal for industrial applications. With a maximum sewing speed of up to 5,500 stitches per minute, it ensures efficient production. Its robust motor and precise mechanical components allow for consistent performance across various fabric types, from lightweight materials to heavy-duty textiles, ensuring high productivity and reliability in demanding environments.

2;2. Stitch Types and Adjustments

The Juki DDL-8700 offers versatile stitch options, primarily focusing on straight-stitch sewing for industrial applications; Stitch length and width can be adjusted to suit various fabrics and sewing requirements. The machine allows for precise control over stitch formation, ensuring consistent results. Proper oil lubrication, such as using Juki’s New Defrix Oil No. 1, is essential for maintaining smooth stitch quality and overall machine performance.

2.3. Industrial-Grade Build and Reliability

The Juki DDL-8700 is built with durable, industrial-grade components, ensuring long-term reliability and high-performance sewing. Its robust construction withstands heavy-duty use, making it ideal for professional settings. Regular maintenance, including oil lubrication and parts replacement with genuine Juki components, is crucial for sustaining its operational efficiency and extending its lifespan in demanding environments.

Technical Specifications

The Juki DDL-8700 features a maximum sewing speed, adjustable stitch length, and a precise needle bar stroke with an efficient hook system, ensuring consistent performance.

3.1. Maximum Sewing Speed

The Juki DDL-8700 achieves a maximum sewing speed of up to 5,500 stitches per minute, making it ideal for high-volume industrial sewing applications. This high-speed performance ensures efficient fabric handling, suitable for both lightweight and heavy-duty materials. The machine’s robust design supports consistent operation, maintaining precision and reliability even at peak speeds.

3.2. Stitch Length and Width

The Juki DDL-8700 offers precise control over stitch length and width, with a maximum stitch length of 4mm and a maximum stitch width of 6mm. These adjustable settings allow for versatility in handling various fabric types, ensuring consistent and professional results. The machine’s mechanical design provides accurate stitch formation, making it suitable for industrial sewing applications that require both durability and flexibility.

3.3. Needle Bar Stroke and Hook System

The Juki DDL-8700 features a robust needle bar stroke designed for high-efficiency sewing, ensuring precise stitch formation. The hook system is engineered to synchronize seamlessly with the needle, providing consistent loop creation for reliable stitching. This advanced mechanism supports smooth operation across various fabric types, maintaining durability and performance. Regular maintenance of these components is essential for optimal machine functionality and longevity.

Safety Precautions

Always follow safety guidelines to avoid accidents. Wear protective gear, ensure proper machine maintenance, and keep the workspace clear to prevent injuries during operation.

4.1. General Safety Guidelines

Always follow essential safety rules to prevent accidents. Ensure the machine is properly oiled with Juki Machine Oil 7 before use. Keep the workspace clean and clear of debris. Avoid wearing loose clothing that could get caught in moving parts. Maintain a safe distance from children while operating. Regularly inspect the machine for wear and tear. Adhere to all guidelines provided in the manual for safe and efficient operation.

4.2. Protective Equipment Recommendations

Wear safety glasses to protect against needle breakage. Ensure loose clothing and long hair are tied back to avoid entanglement with moving parts. Use insulated tools when handling electrical components. Avoid touching hot surfaces like the needle or hook system during operation. Always use protective gloves when handling sharp objects or performing maintenance tasks. Adhere to these guidelines to ensure a safe working environment while operating the Juki DDL-8700 sewing machine.

4.3. Hazardous Materials Information

The manual highlights the use of specific oils like JUKI MACHINE OIL 7 and JUKI NEW DEFRIX OIL No. 1, which require safe handling. Avoid skin contact and ensure proper ventilation when using these oils. Dispose of used oils and materials responsibly, adhering to environmental regulations. Refer to the Safety Data Sheets (SDS) for detailed information on handling and storage of these substances to minimize potential health and environmental risks.

Installation and Setup

Unpack and prepare the machine, install the belt cover and bobbin winder, and adjust the knee lifter height for proper operation. Ensure correct oil lubrication for smooth functionality.

5.1. Unpacking and Preparing the Machine

When unpacking, carefully lift the machine from the box to avoid damage. Inspect for any visible damage or defects. Place the machine on a stable surface and ensure all accessories are included. Before first use, apply Juki Machine Oil 7 to the oil pan up to the HIGH mark. This ensures proper lubrication for smooth operation. Refer to the manual for specific oil application guidelines to maintain machine performance and longevity.

5.2. Installing the Belt Cover and Bobbin Winder

Align the belt cover with the machine’s grooves and secure it firmly to prevent slippage. Attach the bobbin winder by ensuring it fits snugly into its designated slot. Gently press to confirm it is properly seated. Refer to the manual for precise alignment to avoid misinstallation. Ensure all parts are tightly fastened to maintain optimal machine performance and prevent operational issues during use.

5.3. Adjusting the Knee Lifter Height

Loosen the adjustment screws on the knee lifter and position it to your preferred height. Tighten the screws securely to ensure stability. Ensure the lifter moves smoothly without obstruction. Proper adjustment is crucial for efficient fabric handling and even stitching. Refer to the manual for specific torque settings to avoid over-tightening, which may damage the mechanism. This step ensures optimal control during sewing operations.

5.4. Oil Lubrication Requirements

Use Juki-recommended oils like NEW DEFRIX OIL No.1 or MACHINE OIL 7; Fill the oil pan up to the HIGH mark before operation. Refill when the oil level drops below the LOW mark. Proper lubrication ensures smooth operation and prevents mechanical wear. Regular oil checks are essential to maintain performance. Use only genuine Juki parts for reliability. Lubricate monthly or as specified in the manual to uphold machine longevity and efficiency.

Operating the Machine

Start the machine, thread the needle, and select stitches. Follow safety guidelines, ensure proper fabric handling, and maintain consistent speed. Regular oil checks ensure smooth operation and longevity.

6.1. Starting the Machine

Before starting, ensure the machine is placed on a stable surface. Fill the oil pan with Juki Machine Oil 7 up to the HIGH mark. Turn the power switch on and allow the machine to run idle for a few minutes to circulate the oil. Always check the oil level before operation, as running the machine without sufficient oil can cause damage. Proper lubrication ensures smooth performance and extends the machine’s lifespan.

6.2. Threading and Bobbin Setup

Proper threading is essential for smooth operation. Begin by threading the upper part of the machine, following the guide marks. Ensure the bobbin is correctly seated in the bobbin case and thread it through the tension spring. Pull the thread gently to check tension. Use the correct needle size and thread type for your fabric. Always refer to the manual for specific threading diagrams to avoid errors and ensure consistent stitching quality. Regularly check and adjust thread tension for optimal performance.

6.3. Stitch Selection and Adjustment

Select the appropriate stitch type based on fabric thickness and sewing requirements. Use the stitch selection dial or electronic controls to choose from various straight stitch options. Adjust stitch length and width using the provided knobs, ensuring settings match your fabric type. Refer to the manual for recommended settings. Proper needle size and thread type are crucial for consistent results. Always test stitches on scrap fabric before sewing to ensure accuracy and prevent thread breakage.

6.4. Sewing Techniques and Tips

Mastering the Juki DDL-8700 involves using proper techniques for consistent results; Always use the correct needle size and thread type for your fabric. Backstitch at the beginning and end of seams for durability. Maintain steady fabric flow to avoid uneven stitching. Use the knee lifter to raise the presser foot without stopping the machine. Regularly check and adjust thread tension to prevent breakage. Practice on scrap fabric to ensure settings are optimal for your project.

Maintenance and Servicing

Regular lubrication with Juki-approved oils ensures smooth operation. Clean the machine daily, focusing on the bobbin area and feed dogs. Schedule professional servicing annually for optimal performance.

7.1. Daily Maintenance Routine

Daily maintenance involves cleaning the bobbin area, feed dogs, and stitch plate to remove fabric lint and debris. Lubricate moving parts with Juki-approved oils, ensuring the machine runs smoothly. Check and tighten any loose screws, and inspect the needles and hooks for wear. Regularly oiled parts include the hook race and needle bar. Follow these steps to prevent downtime and maintain stitching quality consistently over time.

7.2. Weekly Lubrication Schedule

Perform weekly lubrication to ensure smooth operation. Use Juki-approved oils, such as Juki Machine Oil 7 or Juki New Defrix Oil No. 1, on moving parts like the hook race and needle bar. Apply a few drops to the specified areas, wiping off any excess. Regular lubrication prevents friction, reduces wear, and maintains consistent stitching quality. This routine is essential for extending the machine’s lifespan and ensuring optimal performance.

7.3. Monthly Cleaning and Inspection

Perform a thorough cleaning and inspection monthly to maintain optimal performance. Remove dust and debris from the hook race and other moving parts using a soft brush or compressed air. Lubricate all specified areas with Juki-approved oils. Inspect needles, hooks, and belts for wear or damage, replacing them as needed. Clean the machine’s exterior and ensure all components are tightened properly. Neglecting this routine can lead to mechanical issues and reduced stitching quality over time.

7.4. Recommended Spare Parts and Tools

Keep essential spare parts like needles, bobbin cases, and belts on hand. Use genuine Juki components to ensure compatibility and performance. Regularly inspect and replace worn or damaged parts to maintain stitching quality. Store lubricants like Juki New Defrix Oil No. 1 or Machine Oil 7 for routine maintenance. Always refer to the manual for specific part numbers and tool recommendations to keep your machine in optimal working condition.

Troubleshooting Common Issues

The manual addresses common problems like thread breakage, tension issues, and uneven stitching, providing solutions and maintenance tips to resolve them effectively and ensure smooth operation.

8.1. Machine Not Turning On

If the machine fails to turn on, ensure the power cord is securely connected and the outlet is functioning. Check the circuit breaker or fuse. Verify the power switch is operational and free from damage. Consult the manual for detailed troubleshooting steps to diagnose and resolve the issue promptly, ensuring minimal downtime and continued productivity.

8.2. Thread Breakage or Tension Problems

Thread breakage or tension issues may occur due to incorrect tension settings, improper threading, or using low-quality thread. Check the tension dials and adjust them according to the fabric type. Ensure the thread is properly seated in the tension discs and guide. Re-thread the machine if necessary, and consult the manual for specific tension recommendations to resolve the issue effectively and maintain consistent stitching quality.

8.3. Uneven Stitching or Bobbin Issues

Uneven stitching or bobbin issues can arise from improper bobbin installation or misaligned needles. Check if the bobbin is correctly seated and the case is properly adjusted. Ensure thread tension is balanced and needles are aligned accurately. Inspect the bobbin for damage and re-thread the machine if necessary. Correcting these factors should restore consistent stitching quality and prevent issues.

8.4. Noise or Vibration Abnormalities

Noise or vibration issues may occur due to improper installation, insufficient lubrication, or misaligned parts. Ensure the machine is level and securely fastened to the table. Check for loose screws and tighten them if necessary. Lubricate moving parts with Juki-recommended oil to reduce friction. Replace any worn-out components, such as the needle bar or hook, to eliminate excessive noise and vibrations, ensuring smooth operation.

Accessories and Compatible Parts

The Juki DDL-8700 offers various accessories, including needles, bobbin winders, and oil kits. Ensure compatibility by using Juki-recommended parts for optimal performance and durability of the machine.

9.1. Available Accessories

The Juki DDL-8700 supports various accessories, including bobbin winders, needles, and lubrication oils. Additional parts like hook systems, tension discs, and table extensions enhance functionality. Ensure compatibility by using Juki-approved accessories for optimal performance and machine longevity. Refer to the manual for a detailed list of recommended parts and tools to maintain and upgrade your sewing machine effectively.

9.2. Compatible Needles and Attachments

The Juki DDL-8700 supports a range of compatible needles, including heavy-duty and sharp-pointed options, designed for various fabric types. Attachments like tension discs and hook systems are also available to enhance stitching precision. Always use Juki-approved needles and parts to ensure compatibility and optimal performance. Regularly inspect and replace needles to maintain machine efficiency and prevent damage during operation.

Warranty and Support Information

The Juki DDL-8700 is backed by a comprehensive warranty covering parts and labor. For support, contact Juki’s customer service or refer to the manual for detailed information.

10.1. Warranty Coverage Details

The Juki DDL-8700 warranty covers defects in materials and workmanship for a specified period. It includes repair or replacement of faulty parts, excluding normal wear items. The warranty period varies by region, typically covering one year from purchase. Registration may be required to activate coverage. For full details, refer to the warranty section in the instruction manual or contact Juki’s support team.

10.2. Customer Support Contact Information

For assistance, contact Juki’s customer support team via phone, email, or their official website. Regional offices and authorized dealers provide localized support. The manual includes a dedicated section with contact details, ensuring easy access to help. Users can also visit Juki’s official website for comprehensive support resources and troubleshooting guides.

Environmental Considerations

The manual emphasizes proper disposal of machine parts, recycling guidelines, and compliance with environmental regulations. It also covers handling hazardous materials and eco-friendly maintenance practices.

11.1. Proper Disposal of Machine and Parts

The manual instructs users to dispose of the Juki DDL-8700 and its parts responsibly, adhering to local environmental regulations. It recommends separating recyclable components like metal and plastic, ensuring hazardous materials such as oil and batteries are handled safely. Proper disposal helps minimize environmental impact and complies with eco-friendly practices.

11.2. Recycling Guidelines

The manual emphasizes recycling metal, plastic, and electronic components responsibly. Users are advised to consult local recycling programs for proper handling of machine parts. Donating functional components or repurposing materials is encouraged. Adhering to these guidelines supports environmental sustainability and reduces waste, aligning with eco-friendly practices.

Additional Resources

Additional resources include downloadable PDF manuals, online forums, and communities for troubleshooting and tips. These resources provide comprehensive support for optimal use and maintenance of the machine.

12.1. Downloadable PDF Manuals

The Juki DDL-8700 instruction manual is available for free download in PDF format, offering detailed guides for installation, operation, and maintenance. The manual spans 49 pages, covering technical specifications, safety precautions, and troubleshooting. Users can access it through official Juki websites or trusted third-party sources, ensuring easy reference for professionals and hobbyists alike. Regular updates are provided to keep users informed about the latest features and maintenance tips.

12.2. Online Forums and Communities

Active online forums and communities dedicated to the Juki DDL-8700 provide valuable resources, troubleshooting tips, and user experiences. Platforms like Reddit and specialized sewing groups offer real-time support, allowing users to share insights and solutions. These communities are ideal for addressing specific queries, learning advanced techniques, and staying updated on the latest sewing trends and machine optimizations.